dsengine

Mechanical

- Feb 5, 2005

- 8

Hi there,

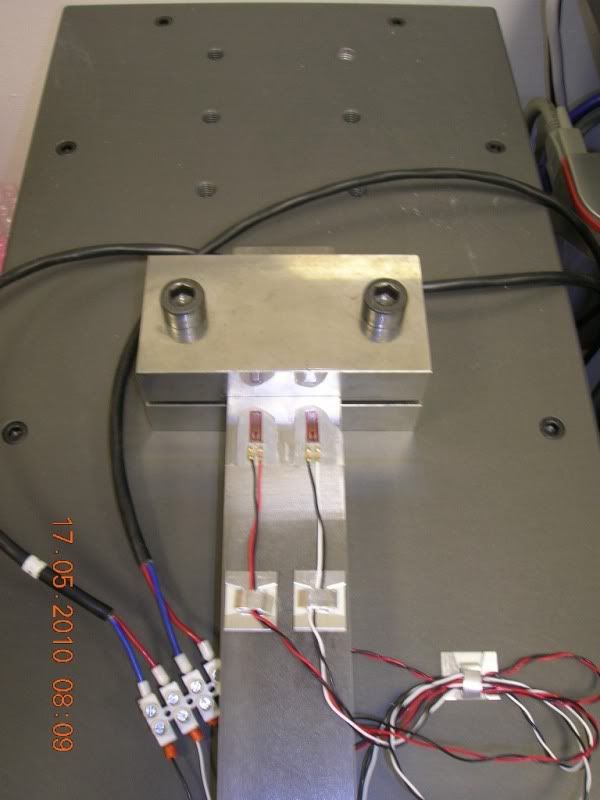

I'm attempting to perform a modal test on a cantilever beam. The idea is to measure the strain at the constrained end using strain gauges, with output to a datalogger. A signal generator and shaker will provide the sinusoidal applied force at the tip. My question relates to how best to transmit this force to the beam.

Currently ball bearings transmit the force to the tip end but the clamp around the ball bearings is fairly massive and I'm worried this will produce inaccurate results. It appears that thin "stingers" might be the solution but I'm not sure how these are attached to the beam. I realise the object is to keep the applied transverse forces to a minimum so that the driving force is purely axial.

Would a tapped plug in the beam be a solution and screwed into the stinger? Or a hole right through the beam and clamped at either end? Or would an epoxy adhesive be more suitable?

Appreciate any advice you can provide. Many thanks in advance.

I'm attempting to perform a modal test on a cantilever beam. The idea is to measure the strain at the constrained end using strain gauges, with output to a datalogger. A signal generator and shaker will provide the sinusoidal applied force at the tip. My question relates to how best to transmit this force to the beam.

Currently ball bearings transmit the force to the tip end but the clamp around the ball bearings is fairly massive and I'm worried this will produce inaccurate results. It appears that thin "stingers" might be the solution but I'm not sure how these are attached to the beam. I realise the object is to keep the applied transverse forces to a minimum so that the driving force is purely axial.

Would a tapped plug in the beam be a solution and screwed into the stinger? Or a hole right through the beam and clamped at either end? Or would an epoxy adhesive be more suitable?

Appreciate any advice you can provide. Many thanks in advance.