Hi all,

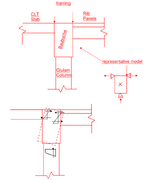

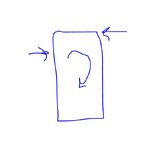

Some of you may be interested in this problem or may even have already encountered this and had a solution. The question is about a clever and efficient detail to avoid unexpected torsion and splitting on a timber beam. The timber beam in question is taking an unequal loading with an eccentricity. You can see the condition on the attached basic sketch and the model to understand the geometry.

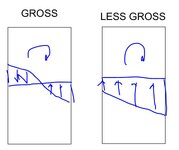

Left hand side is CLT slab and on the right hand side timber rib panels are framed into this hardwood laminated beam known as Baubuche. The unequal loading at the Baubuche beam is causing torsion and the same unequal loading is eccentrically introduced to the Baubuche beam. I thought about having a tension strap at the top that is screwed into CLT, Baubuche and ribs so that everything would be tied together but more I think about it actually the tension tie does not do much when the Baubuche beam rotates creates a compressive stress at the top of the ribs, and tension at the bottom and would do the same on the left hand side and would eventually split in my opinion.

Have you guys had this kind of an issue and maybe even already thought about it and came up with an efficient way to solve this ?

Some of you may be interested in this problem or may even have already encountered this and had a solution. The question is about a clever and efficient detail to avoid unexpected torsion and splitting on a timber beam. The timber beam in question is taking an unequal loading with an eccentricity. You can see the condition on the attached basic sketch and the model to understand the geometry.

Left hand side is CLT slab and on the right hand side timber rib panels are framed into this hardwood laminated beam known as Baubuche. The unequal loading at the Baubuche beam is causing torsion and the same unequal loading is eccentrically introduced to the Baubuche beam. I thought about having a tension strap at the top that is screwed into CLT, Baubuche and ribs so that everything would be tied together but more I think about it actually the tension tie does not do much when the Baubuche beam rotates creates a compressive stress at the top of the ribs, and tension at the bottom and would do the same on the left hand side and would eventually split in my opinion.

Have you guys had this kind of an issue and maybe even already thought about it and came up with an efficient way to solve this ?