paintballJim

Mechanical

- Dec 23, 2009

- 56

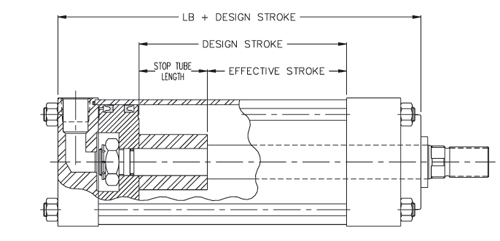

I am attempting to calculate the buckling strength of a hydraulic cylinder and have a question. My book shows that I should use the weakest moment of Inertia section bu8t it would seem that that would be inaccurate. The rod inertia is about 1/4 of the tube. So the question is, do I figure the cylinder as the full length being of the rod and pinned at both ends. Or do I just calculate the buckling strength of the rod and figure the tube end is fixed knowing that the tube is much stiffer than the rod? Or is there a better option. I plan to run a solid-doesn't-Works simulation as well, but I would like to make my mind work a little as well and compare.

Thanks

Jim

Thanks

Jim