RichBolduc

Mechanical

- Aug 23, 2013

- 1

Hi everyone,

New here and have a quick question. I'm pretty sure I've seen similar to this before but a co-worker doesn't think it can be done.

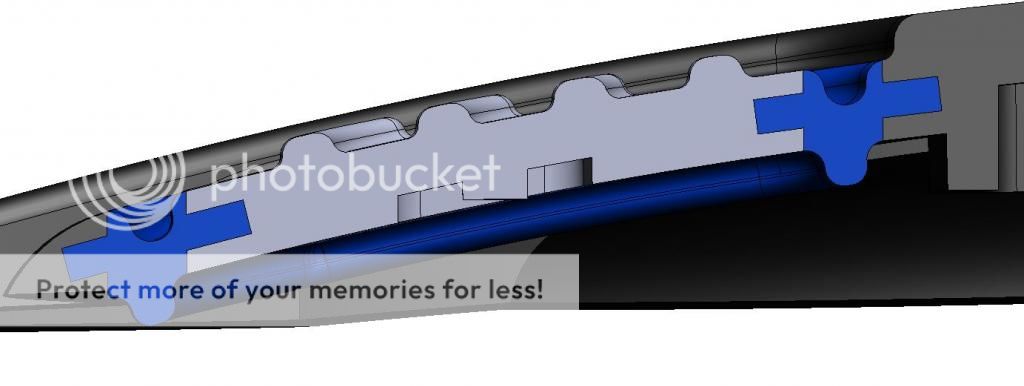

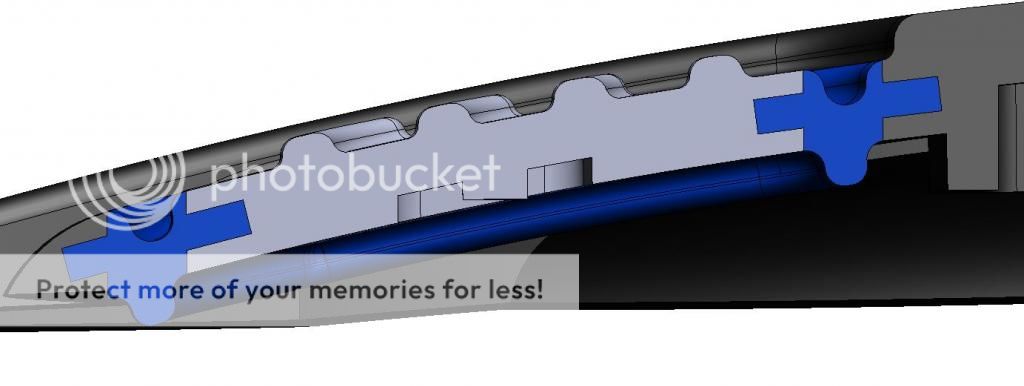

I want to make a button with an over molded rubber (butyl or santoprene I'm thinking) ring. It's going to act like a ring on a speaker, with button section essentially being like a speaker cone. My plan was to mold the ring, then insert that in to a mold and mold the plastic button over it. Here's a pic of what I'm thinking. The dark grey is the main body this will all get over molded into. The blue would be the ring, and then the light grey would be the button. Will a setup like this work? Are there other parts out done like this? He's thinking that the rubber ring wouldn't be able to survive the plastic being molded over it. My reasoning for molding the ring first, then inserting it in to the button mold is to alleviate the undercut on the button where the ring sits. If you've seen it before, any chance you can send me a link to where it's been done like this in the past? Right now we've only spent about 1/2 a day on the design, so it's still really rough.

Thanks in advance,

Rich

New here and have a quick question. I'm pretty sure I've seen similar to this before but a co-worker doesn't think it can be done.

I want to make a button with an over molded rubber (butyl or santoprene I'm thinking) ring. It's going to act like a ring on a speaker, with button section essentially being like a speaker cone. My plan was to mold the ring, then insert that in to a mold and mold the plastic button over it. Here's a pic of what I'm thinking. The dark grey is the main body this will all get over molded into. The blue would be the ring, and then the light grey would be the button. Will a setup like this work? Are there other parts out done like this? He's thinking that the rubber ring wouldn't be able to survive the plastic being molded over it. My reasoning for molding the ring first, then inserting it in to the button mold is to alleviate the undercut on the button where the ring sits. If you've seen it before, any chance you can send me a link to where it's been done like this in the past? Right now we've only spent about 1/2 a day on the design, so it's still really rough.

Thanks in advance,

Rich