curtis74

Automotive

- Sep 28, 2007

- 40

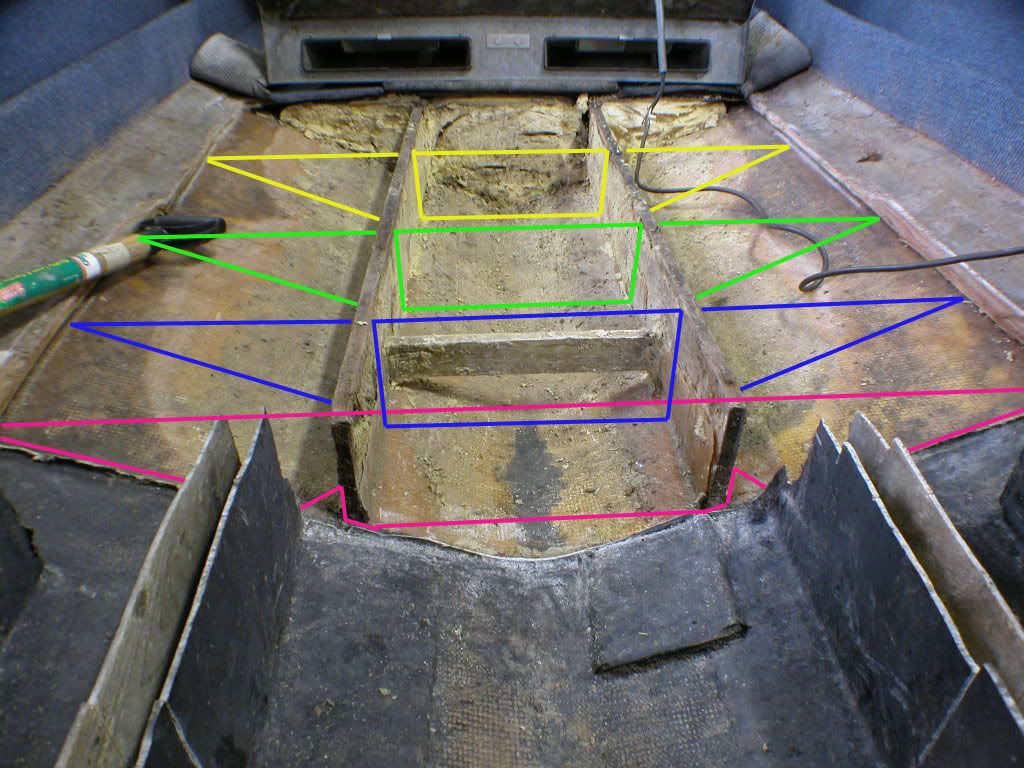

I'm engineering a new boat floor for a customer's boat. He uses the boat very heavily and he's tired of replacing the flooring every few years and wants something a bit more permanent. I've discussed some FRP panels and some monocoque honeycomb skinned panels that would do well, but the cost of materials is rather prohibitive, as is supply when you're only buying two sheets. Here are some examples of things we found that might suit to give you an idea of where I'm going with this:

(specifically the 2016 material)

Is there some way I can make some structural panels myself here at the shop? Concerns are weight, rigidity, and oil/gas resistance. The panels will be sealed from all edges, but if microfissures develop in anything down the road I don't want a the possible hydrocarbon introduction to eat the foam. For the same fissuring reason, I don't want the foam/honeycomb to absorb water. UV won't be much of a concern since we are going to coat the entire floor with Rhino liner.

(specifically the 2016 material)

Is there some way I can make some structural panels myself here at the shop? Concerns are weight, rigidity, and oil/gas resistance. The panels will be sealed from all edges, but if microfissures develop in anything down the road I don't want a the possible hydrocarbon introduction to eat the foam. For the same fissuring reason, I don't want the foam/honeycomb to absorb water. UV won't be much of a concern since we are going to coat the entire floor with Rhino liner.