StrLamp

Structural

- Jan 21, 2022

- 16

Hi

We are designing the pipe support system for gravity and seismic loads, while another party is responsible for the thermal load analysis. Our standard approach is when a pipe is supported from a concrete ceiling or frame using a clevis hanger and threaded rod, and unless it is braced, we consider it a gravity-only support.

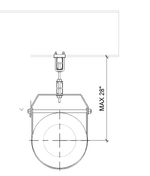

However, the thermal analysis engineer recommends using a minimum rod length of 24 inches, which is not always possible due to pipe alignment and the location of existing structures Otherwise, he treats the support as rigid and applies thermal loads accordingly. In such cases, we would then need to restrain them. I believe he is using CAESAR II for the thermal stress analysis.

Sometimes, we install a small strut frame, and the pipe hangs from a clevis hanger connected to it. Even then, if the rod length is less than 24 inches, he assumes it’s rigid and includes thermal forces. For seismic design, though, we treat these supports as not taking any seismic loads because dedicated seismic restraints are installed at regular spacing.

In my view, the clevis hanger itself provides rotational flexibility, and the rod, even if shorter, still allows some lateral movement. Therefore, these supports should not be treated as rigid unless specifically braced. I’m also aware that shorter rods are stiffer and can attract unintended lateral loads. However, we have seismic restraints installed at regular intervals to address that.

What do you think? Have you had any experience with similar situations?

Thank you.

We are designing the pipe support system for gravity and seismic loads, while another party is responsible for the thermal load analysis. Our standard approach is when a pipe is supported from a concrete ceiling or frame using a clevis hanger and threaded rod, and unless it is braced, we consider it a gravity-only support.

However, the thermal analysis engineer recommends using a minimum rod length of 24 inches, which is not always possible due to pipe alignment and the location of existing structures Otherwise, he treats the support as rigid and applies thermal loads accordingly. In such cases, we would then need to restrain them. I believe he is using CAESAR II for the thermal stress analysis.

Sometimes, we install a small strut frame, and the pipe hangs from a clevis hanger connected to it. Even then, if the rod length is less than 24 inches, he assumes it’s rigid and includes thermal forces. For seismic design, though, we treat these supports as not taking any seismic loads because dedicated seismic restraints are installed at regular spacing.

In my view, the clevis hanger itself provides rotational flexibility, and the rod, even if shorter, still allows some lateral movement. Therefore, these supports should not be treated as rigid unless specifically braced. I’m also aware that shorter rods are stiffer and can attract unintended lateral loads. However, we have seismic restraints installed at regular intervals to address that.

What do you think? Have you had any experience with similar situations?

Thank you.