Enhineyero

Structural

- Sep 1, 2011

- 285

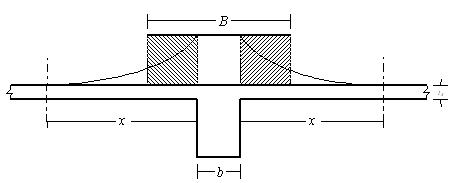

I was wondering, why is the T-beam effective width a function of the span length? or to be more precise for relevant codes a function of the points of contraflexure for sagging bending moments.

Hope someone could help

Hope someone could help