TRAK.Structural

Structural

- Dec 27, 2023

- 321

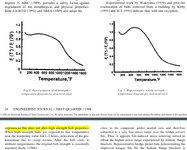

Looking for folks with experience evaluating steel structures that have been exposed to fire/heat. I've read some reference material/articles about general evaluation processes but its a bit of a mixed bag. Some say more or less that if it hasn't deformed than its generally ok. Others say that coupons should be taken for testing. Is there more recent info out there that is generally accepted that offers an evaluation procedure?

Additionally, when looking for deformation, is the standard of care just a visual inspection or are we talking about Lidar scanning to detect miniscule variations?

For reference, I've been asked if I want to evaluate a local auto body shop that had a recent fire. Its a couple bay PEMB structure so nothing super crazy.

Additionally, when looking for deformation, is the standard of care just a visual inspection or are we talking about Lidar scanning to detect miniscule variations?

For reference, I've been asked if I want to evaluate a local auto body shop that had a recent fire. Its a couple bay PEMB structure so nothing super crazy.

![[shadessad] [shadessad] [shadessad]](/data/assets/smilies/shadessad.gif)