EngDM

Structural

- Aug 10, 2021

- 706

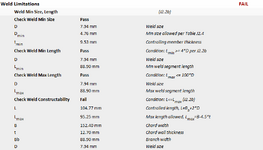

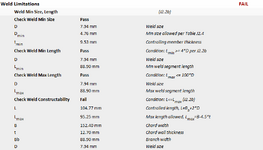

I'm working on the connections in an HSS truss, and I am spot checking with Risa connection when I noticed that, if the width of your branch member width + 2*weld D exceeds the workable flat of the HSS chord, it doesn't allow you to proceed with the calculation. I've screenshotted their report below:

However, we have received structural steel shop drawings (when we are EOR) where the weld does not pass this same check, and fillet welds are still used all around.

Realistically I could groove weld the branch to the chord, but I know I've seen fillets used even though they don't "pass" this check which are much more cost effective.

However, we have received structural steel shop drawings (when we are EOR) where the weld does not pass this same check, and fillet welds are still used all around.

Realistically I could groove weld the branch to the chord, but I know I've seen fillets used even though they don't "pass" this check which are much more cost effective.